I-Glass Design idinga ukubhekwa ngokuphelele: Umqondo wokumodela womkhiqizo (ubuqambi, umgomo, inhloso), umthamo womkhiqizo, uhlobo lomkhiqizo, inhloso yomkhiqizo, njll. Ake sibheke ukuthi kwakhiwa kanjani ibhodlela lengilazi.

Izidingo ezithile zamakhasimende:

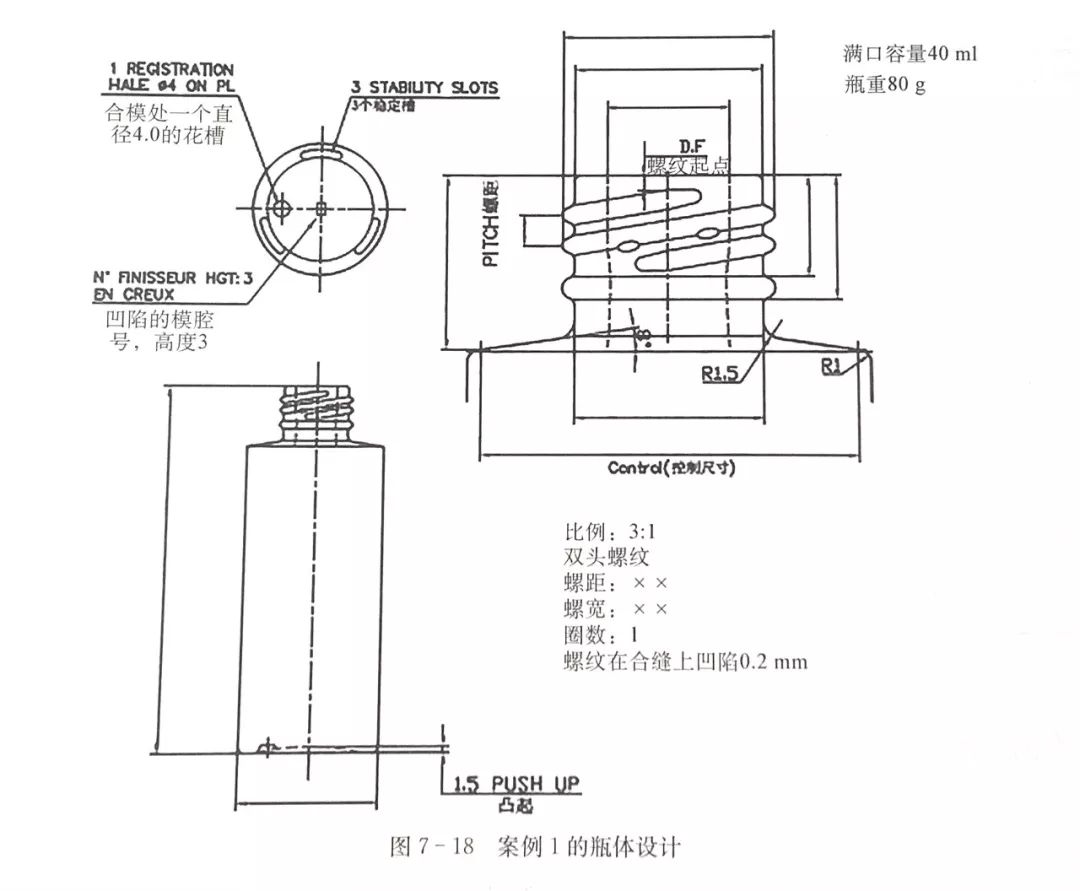

1. I-COSMETICS - I-Essence Bomples

2. Ingilazi esobala

3. I-30ml yokugcwalisa amandla

4, nxazonke, isithombe esithambile kanye nokubucayi phansi

I-5. Izobe ifakwe i-dropper futhi ine-plug yangaphakathi

6

Kunikezwa iziphakamiso ezilandelayo:

1. Ngoba kungumkhiqizo ophelele wokuphela komqondo, kunconywa ukusebenzisa ingilazi emhlophe ephezulu

2. Uma ucabanga ukuthi umthamo wokugcwalisa udinga ukuba ngu-30ml, umlomo ogcwele kufanele okungenani ube nomthamo wama-40ml

3. Sincoma ukuthi isilinganiso sobubanzi siye ekuphakameni kwebhodlela lengilazi ngu-0,4, ngoba uma ibhodlela lincane kakhulu, lizokwenza ukuthi ibhodlela lithelwe kalula ngesikhathi senqubo yokukhiqiza nokugcwaliswa.

4. Uma ucabanga ukuthi amakhasimende adinga ukwakheka okuphansi okuphansi, sinikezela ngesilinganiso esingu-2.

5 Futhi ngoba kukhona i-plug yangaphakathi okufanele ifaniswe, ukulawulwa kwangaphakathi kwesilinganiso somlomo webhodlela kubaluleke kakhulu. Ngokushesha sacela ukudweba okuthile kwe-plug yangaphakathi ukuze kunqunywe ukujula kokulawulwa kwamanani angaphakathi.

I-6. Ngokucutshungulwa kwangemva kokusebenza, kucatshangelwa izidingo zamakhasimende, sincoma ukufafaza ngezigaba kusuka phezulu kuya ku-bafter ukuxhumana namakhasimende, yenza umbhalo othize womkhiqizo, umbhalo wokuphrinta wesikrini, kanye ne-bonsizing yombhalo.

Ngemuva kokuxhumana namakhasimende, yenza imidwebo ethile yomkhiqizo

Lapho ikhasimende liqinisekisa umkhiqizo ngomdwebo futhi liqala ukwakheka kwesikhunta ngokushesha, kudingeka sinake ngokukhethekile amaphuzu alandelayo:

1. Ngomklamo wokuqala wokubumba, umthamo owedlulele kufanele ube mncane ngangokunokwenzeka, ukuze uqinisekise ukushuba phansi kwebhodlela. Ngasikhathi sinye, kuyadingeka futhi ukunaka ihlombe elincanyana, ngakho-ke ingxenye ye-wagrer yesikhunta sokuqala kufanele yakhelwe ukuba ibe yiflethi ngangokunokwenzeka.

2

Ngokusho komklamo wokubumba, kuzokwenziwa iqoqo lezikhunta kuqala, uma kungukuthotshwa kabili, kuzoba amasethi amabili okubumba, uma kungukudonswa kwezintathu, kuzoba yisibumba esinezingcezu ezintathu, njalonjalo. Le sethi yezikhunta isetshenziselwa ukukhiqizwa kwesivivinyo emugqeni wokukhiqiza. Sikholwa ukuthi ukukhiqizwa kwesivivinyo kubaluleke kakhulu futhi kuyadingeka, ngoba kudingeka sinqume ngesikhathi senqubo yokukhiqiza isivivinyo:

1. Ukunemba kokubumba komklamo;

2. Thola amapharamitha okukhiqiza, njengokushisa kwe-Drip, izinga lokushisa elibumba, ijubane lomshini, njll;

3. Qinisekisa indlela yokufaka;

4. Ukuqinisekiswa kokugcina kwebanga lekhwalithi;

I-5

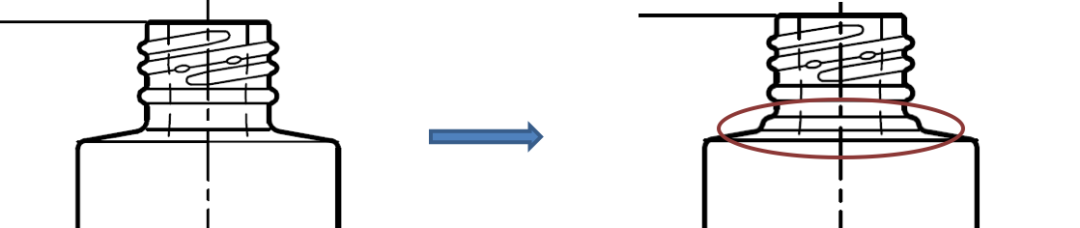

Yize sinake kakhulu ukusatshalaliswa kwengilazi kusukela ekuqaleni, ngesikhathi sokukhiqiza isivivinyo, sathola ukuthi ubukhulu bamabhodlela obuncane bebengaphansi kwe-0.8mm, obekungaphezu kokwamukelekayo kwe-SGD ngoba sasicabanga ukuthi ubukhulu bengilazi bungaphansi kwe-0.8mm bekungaphephile ngokwanele. Ngemuva kokuxhumana namakhasimende, sanquma ukwengeza igxathu engxenyeni yehlombe, ezosiza ukusatshalaliswa kwengilazi ngehlombe.

Bona umehluko esithombeni esingezansi:

Enye inkinga ukulungele i-plug yangaphakathi. Ngemuva kokuhlolwa ngesampula yokugcina, ikhasimende lalinomuzwa wokuthi ukufaneleka kwe-plug yangaphakathi kwakuqinile kakhulu, ngakho-ke sanquma ukukhulisa ububanzi bomlomo webhodlela ngo-0,1 mm, bese beklama ukwakheka komgogodla ukuze ube thwala.

Ingxenye ejulile yokucubungula:

Lapho sithola imidwebo yekhasimende, sithole ukuthi ibanga phakathi kwelogo elidinga ukubopha kanye negama lomkhiqizo elingezansi lincane kakhulu ukuthi lizokwenziwa ngokuphrinta i-bronzing futhi futhi, futhi sidinga ukwengeza esinye isikrini sokukhiqiza. Ngakho-ke, siphakamisa ukwandisa leli banga kuya ku-2,5 mm, ukuze sikwazi ukukuqedela ngokuphrinta kwesikrini esisodwa kanye nokubhula okukodwa.

Lokhu akunakuhlangabezana nezidingo zamakhasimende kuphela kepha futhi gcina izindleko zamakhasimende.

Isikhathi Sokuthumela: APR-09-2022